Tackling Spot Spraying’s Core Challenges

As outlined by Dave, one of the biggest frustrations in spot spraying has always been the inconsistency of chemical delivery, especially during the transition from side-safety (blanket) spraying to single-spot mode. This often led to underdosing, when only a small nozzle was used, or overdosing, when multiple larger nozzles engaged unnecessarily.

The ARAG FlowTRON system, with its Pulse Width Modulation (PWM) control, solves this elegantly. By pulsing nozzles on and off up to 30 times per second, FlowTRON allows for precise control over duty cycle (how long a nozzle is active during each pulse). This means chemical application is consistent across variable speeds and nozzle sizes, ensuring accurate delivery with no waste, no drift, and no regulatory risk—especially important with sensitive products like 2,4-D.

Innovative System Design That Works in the Field

The FlowTRON system is designed as a complete, end-to-end solution. As Dave highlights, its components are built to work seamlessly:

The IBX100 ISOBUS display provides intuitive in-cab control, enabling dynamic rate adjustments and turn compensation.

Cable Smart Drivers (CSDs) efficiently manage nozzle operation, supporting up to four nozzles per unit.

FlowTRON solenoid valves ensure high flow and reliability with low power consumption.

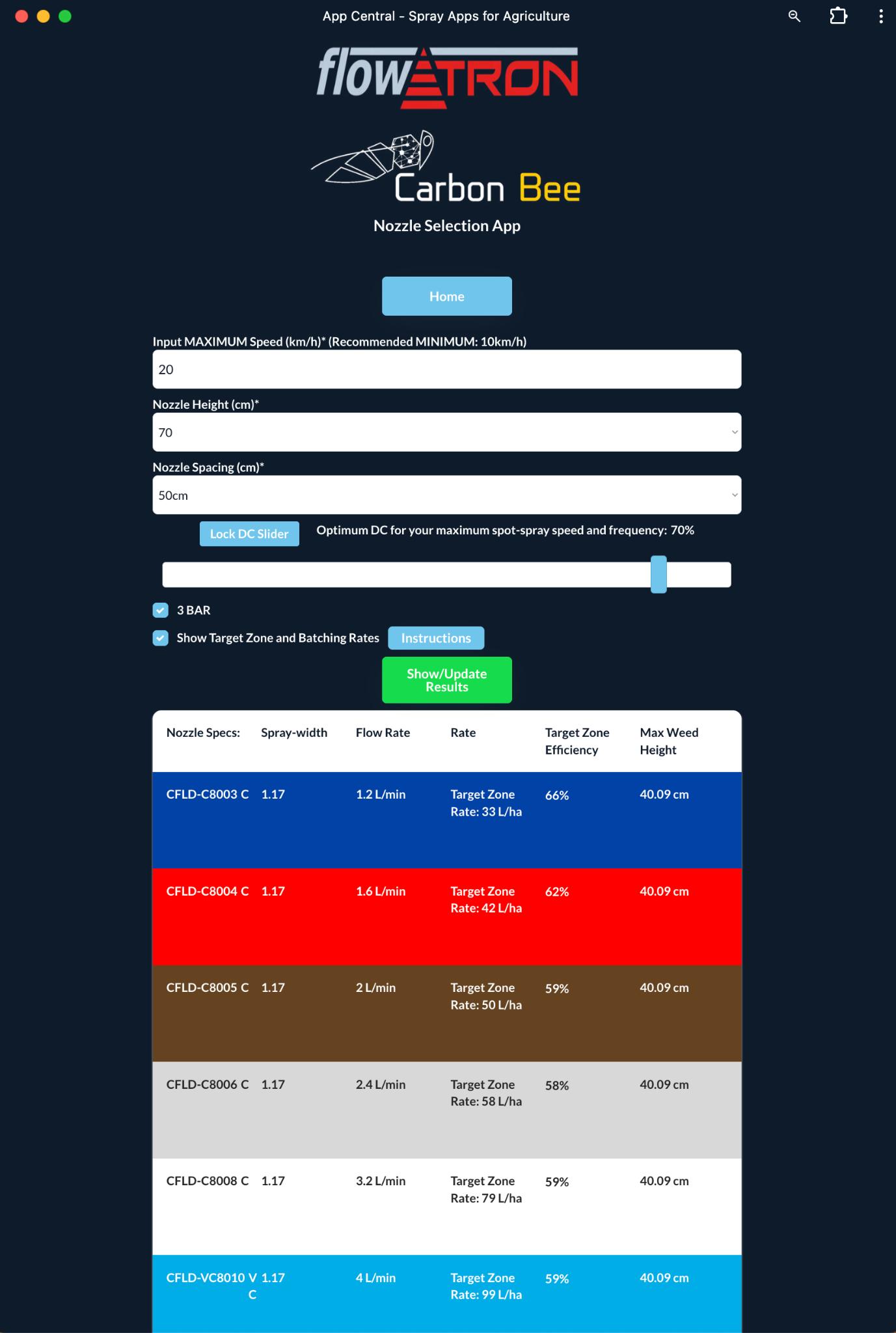

Compact Fan Low Drift (CFLD) nozzles, purpose-built for this system, provide coarse spray qualities tailored to Australian conditions and regulations.

Together, these elements provide a system that’s not just precise—but practical, rugged, and ready for real-world farms.

The Carbon BEE Edge: Smarter Spraying Through Vision and AI

While ARAG FlowTRON optimises how chemicals are applied, Carbon BEE takes care of where they’re needed. Using high-resolution multispectral cameras and advanced AI, Carbon BEE identifies weeds in real time—distinguishing them from crops and soil with unmatched accuracy.

Here’s how Carbon BEE enhances the system:

Precision Detection: Scans the ground as the sprayer moves, detecting only the exact spots needing treatment.

AI-Driven Targeting: Goes beyond basic green detection, classifying weed species and growth stages for tailored application.

Real-Time Sync: Instantly communicates with FlowTRON to activate the correct nozzle at the correct duty cycle—without delay.

Data Collection: Captures valuable field data that can be used for mapping, input planning, and long-term farm strategy.

Scalability: Designed for broad-acre farms, Carbon BEE performs reliably across diverse terrains and under harsh conditions.

This synergy of visual detection and real-time nozzle control results in fewer chemicals being used, better outcomes being achieved, and environmental compliance being confidently met.

METLAN’s Perspective

We see the FlowTRON / Carbon BEE integration as more than an upgrade—it’s a step-change in the future of agricultural spraying. At METLAN, we support and distribute technologies that align with our core values: smarter inputs, stronger yields, and more sustainable farming practices.

Dave Young’s technical breakdown of the system reinforces what we already know—this isn’t just innovation for innovation’s sake. It’s about practical performance, cost efficiency, and long-term agronomic benefit.

See It for Yourself

Curious about what FlowTRON and Carbon BEE can do on your farm? Reach out to the METLAN team to schedule a personalised in-field demonstration or consultation.

And for a deeper dive into the technology, we recommend visiting the original article by Dave Young, along with other valuable insights, on the Fantastic Nozzles website:

👉 Read more here